Where I Work: See how Stickbulb’s first-ever showroom is lighting up Long Island City

6sqft’s series “Where I Work” takes us into the studios, offices, and businesses of New Yorkers across the city. In this installment, we’re going inside the new Long Island City showroom of Stickbulb, a sustainable light fixture company. Want to see your business featured here? Get in touch!

Before opening their first showroom, sustainable lighting brand Stickbulb had just one wire rack of shelving and one workbench, with their supplies spilling out into the communal areas of their building. They desperately needed more space. The company found it this year in a 10,000-square-foot former steel factory in Long Island City. With its terracotta walls and wooden floors, not only does the new space aptly complement Stickbulb’s modern LED light fixtures, but the former factory gives them enough room to show off how their products are made and the people who make them.

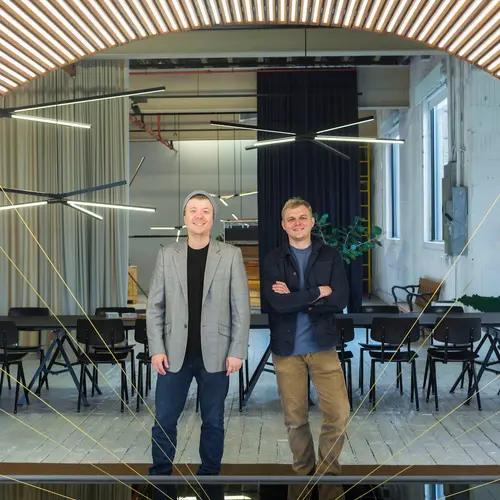

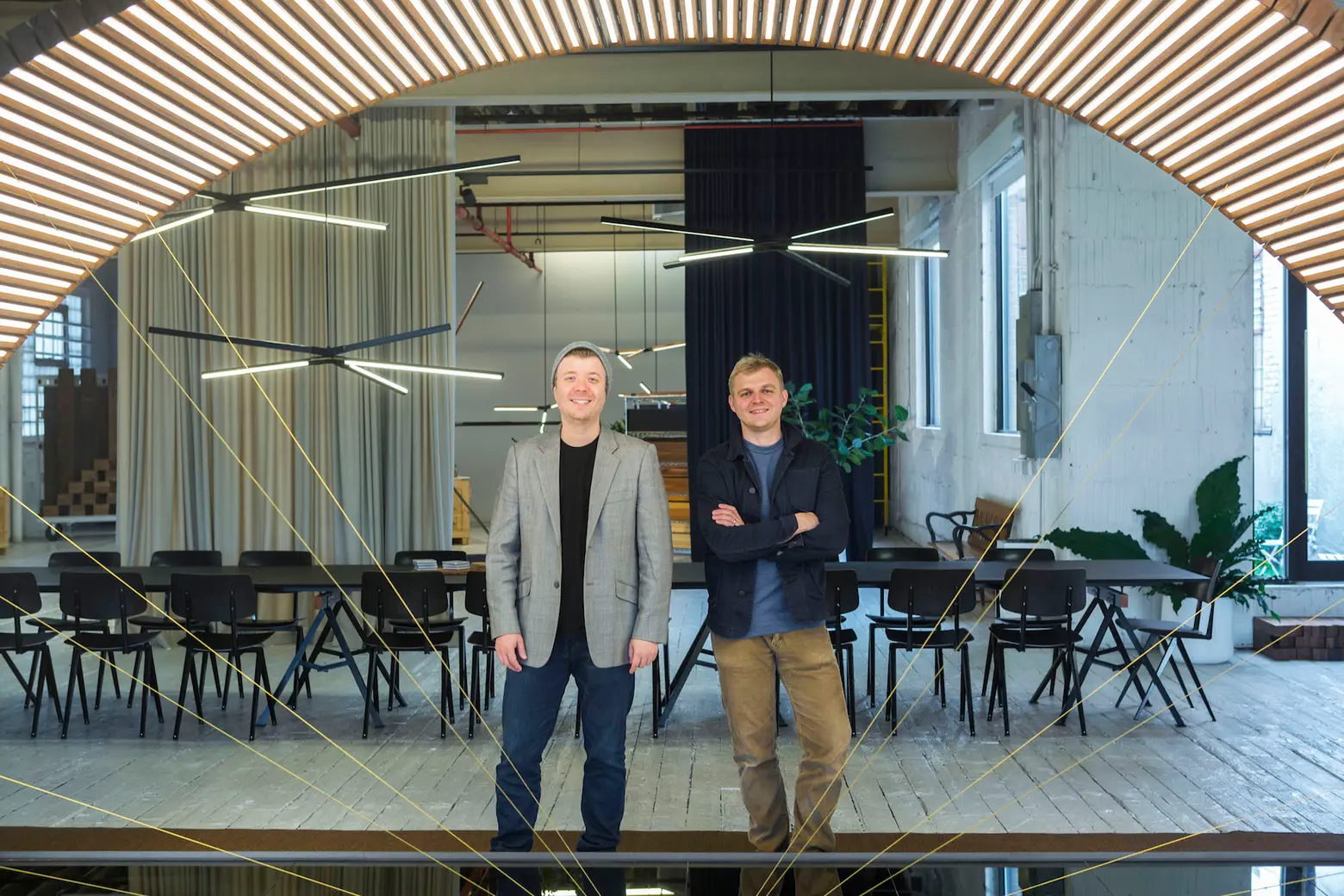

Sustainability remains a core mission for Stickbulb, which was founded six years ago by Russell Greenberg and Chris Beardsley, the creative team behind RUX Design. Using salvaged wood from demolished buildings and dismantled water towers, Stickbulb products always have a story to tell. “The idea is that the customer can trace back the wood that they have in their light fixture back to the original building it was a part of,” Russell told us during a recent visit to the company’s showroom. Ahead, take a tour of Stickbulb’s new space and hear from Russell and Chris on starting the studio, the process behind finding reclaimed wood, and the bright future of the growing company.

Stickbulb’s “Sky Bang” light fixture hangs above their 24-foot-long table, also made in-house

Russell and Chris chose this Long Island City building for its open floor plan, wood floors, column-free space, and internal courtyard

Can you tell us how Stickbulb began? How did you two meet?

Russell: We were friends in an architecture studio undergraduate program at Yale University, collaborated all the time on stuff, and liked working together. And then we graduated and both interned at Robert A.M. Stern Architects, he was the dean of Yale at the time, we were in the model shop there together. Then we went back to graduate school there, collaborated there too. Graduated. Went our separate ways. And then came back together through RUX and Stickbulb.

I started RUX in 2008 as a product design multi-disciplinary architecture studio place. It evolved away from client work and towards building our own stuff in-house, thanks to the success of Stickbulb, which was an idea that came out of the studio in 2011 and then became formalized in the creation of the new company Stickbulb in 2012.

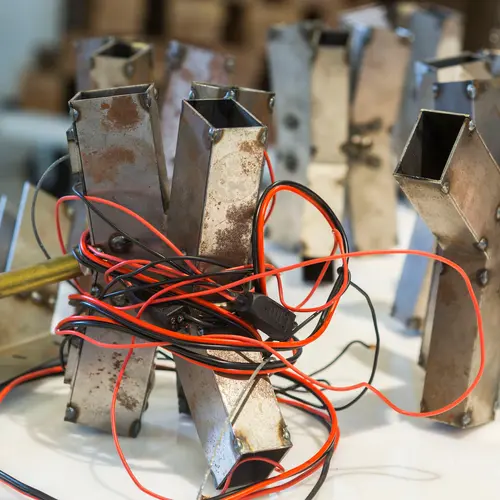

Chris: We started with a line of portable light fixtures that were all based on a plug and play system of wooden sticks with embedded LED and then a couple different metal connector pieces that would hold them as either floor lamps or table lamps.

And then over the past six years, we’ve been constantly iterating on that system – leaving the sticks basically as the common element, and just changing the metal hardware connector pieces so that the same sticks can be held together to form an array of different light fixtures, now linear pendants, chandeliers, wall sconces, even pieces that sit on the floor as furniture like a small side table.

The company’s design, production, sales, marketing, and showroom all sit under one roof.

What is the design process like?

Russell: Everything is always a dialogue. We collaborate on everything, it’s a very collaborative environment.

Chris: I would say it’s not an idea for a specific shape or form and then drilling down how we make that, it’s more from the ground up. From using the parts that we have that are part of our system and kind of thinking what’s possible by making some small but strategic little changes that open up the ability to significantly different things by making a few small changes.

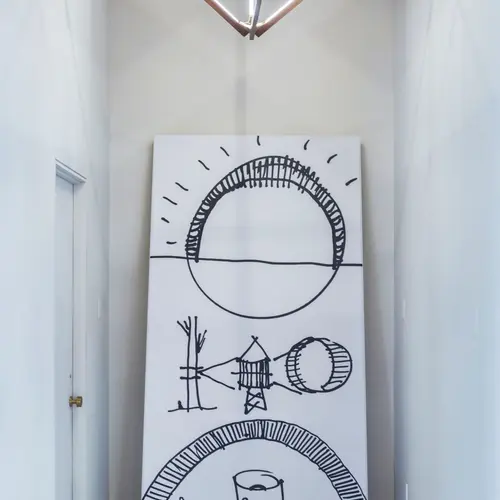

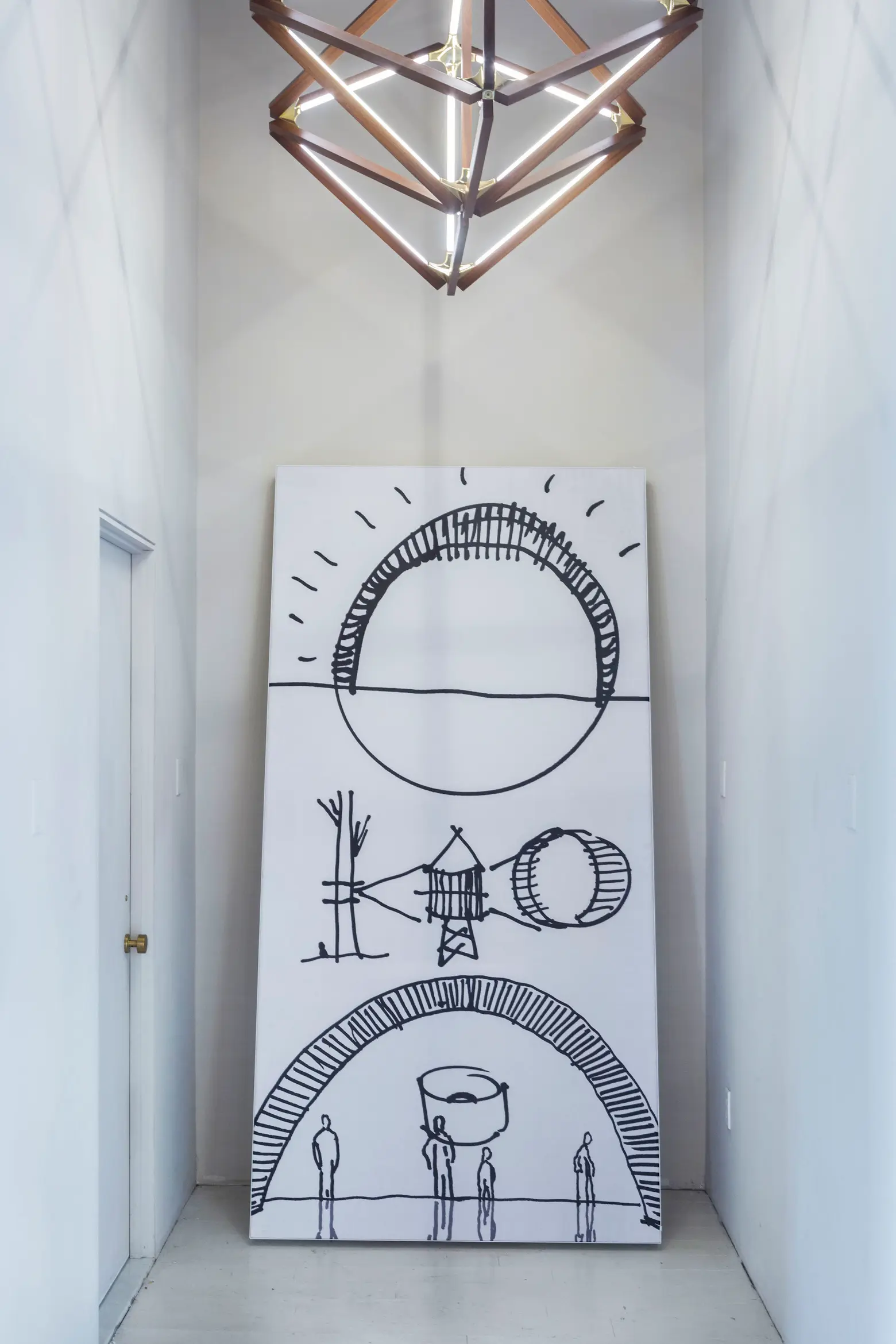

Russell’s sketch of a water tower inspired the showroom’s illuminated art piece, “Ambassador”

Explain the art piece, “Ambassador,” in the entryway of the showroom and how its design came to be.

Russell: We had the shape and we had to figure out how to do it. So the immediate thing when you look at Stickbulb is, ‘oh linear sticks, shapes, nice geometries.’ But these sticks that can’t actually speak for themselves are trying to tell you the story of where they came from. And a big part of what we do here is try to give these sticks that voice in a way we market the products and the imagery that we put next to the products. And also genuinely sourcing the wood we get from interesting, reclaimed sources.

When we finally figured out how to get a steady stream of high-quality, redwood from dismantled water towers, we felt that was a big idea and an exciting moment and we wanted to pay homage to that with a sculpture of some kind. So the question was, how do you get this wood to speak about its past without actually putting words next to the wood? So the premise was to take the scale of the redwood and bring it into the urban context through this big circle.

Why use wood from water towers?

Russell: It’s a pretty iconic part of New York and a lot of urban centers in the Northeast.

Chris: And the nature of water towers is they have about a 40-year useful life, so when they reach the end of the 40-year useful life, they get replaced. So there’s a constant replenishment, and therefore a supply of wood that’s coming from the old water towers. And it can’t be used as a water tower anymore, but it’s still really good and valuable wood.

Because when they’re building water towers, they’re picking the highest grade of wood to build them from, because they have to be free of knots, free of cracks, twisting, so getting that material is some of the best wood you can get, especially some of the ones being dismantled now.

Russell: It’s also a really good way for us to try to balance the modernity and sleekness of our product with the depth of history. So it was a good storytelling vehicle for us as well as a genuine source of wood that’s really beautiful. It checked all of the boxes.

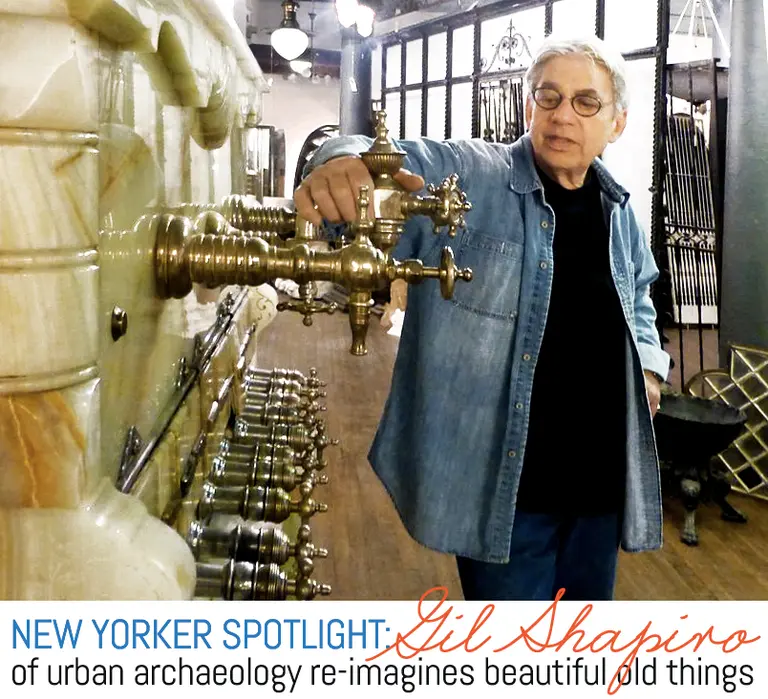

The photo shows the Pullman Couch Company Factory in Chicago which had caught fire in 2013 in the middle of winter. Water from the hoses of the firefighters had frozen on the outside, while the fire still burned inside. Much of Stickbulb’s inventory, including the light fixture shown above, was salvaged from this building, nicknamed “Fire and Ice.”

“It’s a story of a beautiful building that died in a really beautiful way, ” Russell told us. Because the building was built in the 1800s, the wood they salvaged is no longer being harvested today.

How do you get the wood?

Russell: There are middlemen, there are direct sources, there’s a market for it, for sure. If you wanted to get some, you could get your hands on some.

Chris: But we’ve established a network of people that go out and source the wood themselves when water towers are coming down.

And there’s the sustainability factor.

Russell: Oh, of course. I mean it goes without saying so much that we forgot to say it. That’s at the core of a lot of the things that we do here. And most of the time, when we make decisions at this point, it’s already a part of the decision-making process.

The vision behind the showroom was to be as flexible as possible, using curtains to open up or divide the space

Did you found the company with sustainability in mind?

Russell: Absolutely. The idea for Stickbulb came from a bunch of wasted sticks that were lying in the corner of a woodshop. And that moment of inception is sort of that DNA of taking something which otherwise may not be used or go in the trash, or returned, is sort of fundamental to the process here.

It’s wood that isn’t being harvested today. So it’s the kind of wood that you can’t get anywhere else, other than salvaging it from old buildings. And if you’re salvaging things from old buildings, we like the idea that we’re highlighting the story and sourcing it not only from known sources. The idea is that the customer can trace back the wood that they have in their light fixture, back to the original building it was a part of.

With the fixture above, the company is testing how big one piece can go

What did your business look like before opening this showroom?

Chris: We were located a few blocks away in Long Island City. We were in a space that we started in that was kind of suites of offices so when Stickbulb first began it was literally one wire rack of shelving, one workbench, and that was where everything was stored and assembled and shipped from. That was when we were doing one or two orders a month and then over the years, it grew and grew. We got some other space down the hall, next door, and then across the hall, and then we were spilling out into the communal areas and we were kind of cobbling together a lot of spaces. We were separated physically and we were just bursting at the seams, literally. So the time came to look for new space.

Russell: And now its weird because there’s so much extra space in here we don’t know what to do with it.

Chris: It was always the dream to have space where we can have everything under one roof: design, production, sales and marketing, and also showroom and display. We wanted to have a place where people could come see the end products that we make, but also see how we make them and the people that make them. Because it’s something we’re really proud of.

How did you come up with the design for the showroom?

Russell: We’re trained architects so it was fun to get back into that and mess around. We’re also playing with our own money so that inherently limited the number of things we could do, but I actually think that worked out to our benefit.

Any plans to expand further?

Russell: Give us some time. It’s sort of like asking someone who just had a baby, ‘when are you going to have a baby?’ I feel like getting here was this was a big moment for us- like every year something else is going on. I wouldn’t call it putting out a fire, but we’re trying to solve a very immediate problem. The very immediate problem was moving into a space, setting up a space, and now we’re in a period where we’re actually trying to enjoy it. Plus, we have plenty of space to expand here if we are to grow.

RELATED:

- Cannoli, cheesecake, and an East Village icon: See history in action at 125-year-old Veniero’s Pastry

- Where I Work: Paulie Gee’s Slice Shop is dishing out retro pizzeria vibes in Greenpoint

- Where I Work: The Four Freedoms Park team talks Louis Kahn, FDR, and preserving a legacy

All photos by Kate Glicksberg exclusively for 6sqft. Photos are not to be reproduced without written permission from 6sqft.