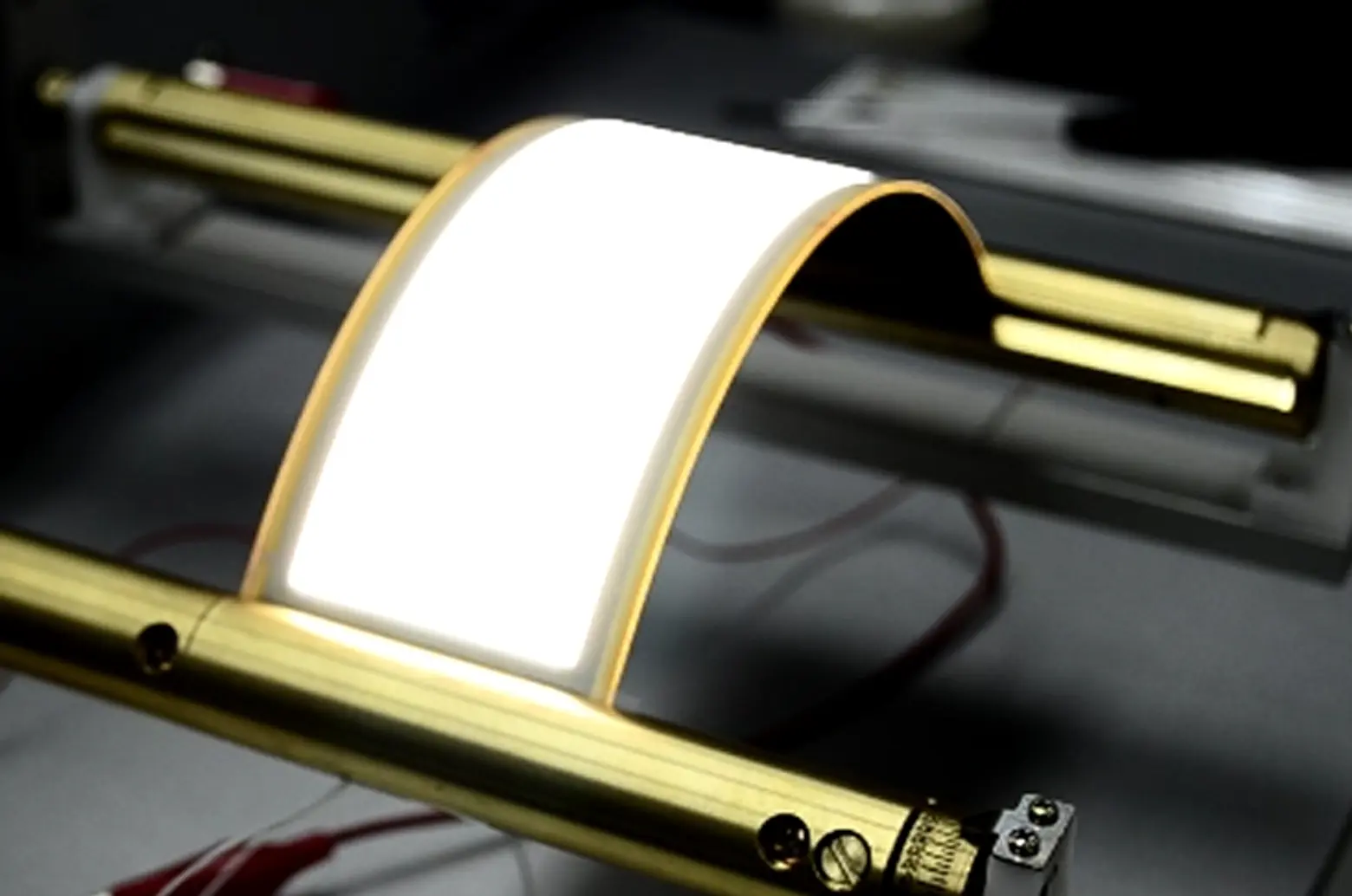

World’s First OLED Panel Will Bring Buildings 40,000+ Hours of Energy-Efficient Lighting

New York buildings racking up big energy bills may soon be able to breathe a sigh of relief. Thanks to new OLED (Organic Light Emitting Diode) technology, lighting will be getting greener, healthier and much more energy efficient.

This November, LG Chem, Korea’s largest chemical company, will bring their new OLED panels into production. The new panels will boast 100 lumens per watt, a life of 40,000+ hours (a world’s best, outperforming Osram, Philips, and Panasonic; and almost on par with conventional LEDs), and be flexible enough to be used in everything from automotive to architecture. Currently plans are to focus distribution on markets in North America and Europe, and so far LG Chem has secured contracts with more than 50 lighting companies, including Atlanta-based Acuity Lighting.

Image © LG Chem

Image © LG Chem

OLED is an organic materials-based light source in which a layer—the emissive layer—gives off light when exposed to electrical currents. Unlike conventional lamps, OLEDs are a more human-health-friendly as the lights are glare-free, heat-free and do not emit UV rays. Moreover, because they are so thin, light, and can flexed, they can easily integrated into an array of building typologies irregardless of architecture.

Acuity Lighting, a major proponent for OLEDs and one of LG’s contractees, writes on their site: “We’ve discovered that OLEDs yield higher application efficiency over conventional lighting…Compared to other types of lighting systems predominantly used for commercial and institutional lighting, discrete low-luminance tiles of OLED lighting can create a lighting system that makes significant improvements in application efficiency.”

Though the technology is here, due to high costs, how quickly it will spread remains up in the air. Currently an OLED is more than five times as costly as an LED ($20 vs. $100, as reported by Korea Biz Wire). However, if demand kicks in and production kicks up, the company believes they will meet economies of scale and prices will eventually move down closer to that of LEDs.

As LG Chem told Korea Biz Wire, “We could increase the production yield significantly by applying a new OLED material. Once we begin the mass-production of the devices in earnest, we will be able to reduce the unit cost almost as low as that of LED lights.”

Hopefully we’ll soon see OLEDs outfitting NYC homes and offices.

[Via Phs.org via Korea Biz Wire]

Lead image © LG Chem